10 Best Wire Welders 2025 in the United States

Winner

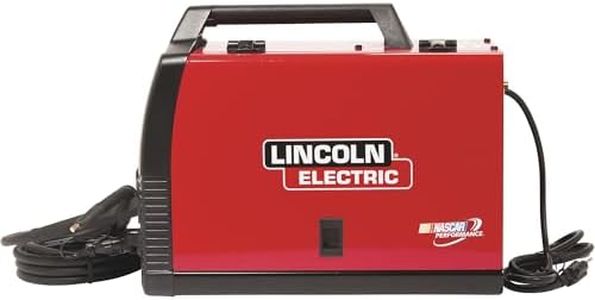

Lincoln Electric 90i FC Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5255-1

The Lincoln Electric 90i FC Flux Core Wire Feed Welder is an excellent choice for anyone looking to tackle small welding jobs, whether at home or on a construction site. Its lightweight design (just 15 lbs) and shoulder strap make it highly portable, ideal for maintenance work or mobile applications. With a 120V power source, you can easily plug it in anywhere, and it effectively welds materials up to 1/4" thick, making it suitable for various DIY projects and light repairs.

Most important from

579 reviews

Lincoln Electric Power MIG 211i MIG Welder K6080-1

The Lincoln Electric Power MIG 211i MIG Welder K6080-1 is a versatile welding machine that caters well to both beginners and experienced welders. One of its standout features is the dual input voltage capability, allowing you to use it with both 120V and 230V power sources, making it suitable for a variety of environments. The welder’s lightweight design at only 41 lbs enhances its portability, which is ideal for moving around a shop or taking to job sites. Additionally, the ergonomic case and included Magnum Pro 100L Welding Gun ensure comfort and control during use, helping to reduce hand fatigue over longer welding sessions.

Most important from

67 reviews

Top 10 Best Wire Welders 2025 in the United States

Winner

9.8 score

Lincoln Electric 90i FC Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5255-1

Lincoln Electric 90i FC Flux Core Wire Feed Weld-PAK Welder, 120V Welding Machine, Portable w/Shoulder Strap, Protective Metal Case, Best for Small Jobs, K5255-1

Chosen by 1296 this week

Lincoln Electric Power MIG 211i MIG Welder K6080-1

Lincoln Electric Power MIG 211i MIG Welder K6080-1

Lincoln Electric FC90 Flux Core Wire Feed Welder and Gun, 90 Amp, 120V, Inverter Power Source for Easy Operation, Portable Shoulder Strap, Best for Small Welding Jobs

Lincoln Electric FC90 Flux Core Wire Feed Welder and Gun, 90 Amp, 120V, Inverter Power Source for Easy Operation, Portable Shoulder Strap, Best for Small Welding Jobs

Millermatic® 142 MIG Welder

Millermatic® 142 MIG Welder

Hobart 500553 Handler 210 MVP MIG Welder - Empower Your Welding with Precision and Power Small

Hobart 500553 Handler 210 MVP MIG Welder - Empower Your Welding with Precision and Power Small

Miller 907614 Millermatic 211 MIG Welder - Portable Flux-Core & MIG Welding Machine with Multi-Voltage Plug for 120V or 240V - Inverter Technology Miller MIG Welders - MIG & Flux Core Welder Machine

Miller 907614 Millermatic 211 MIG Welder - Portable Flux-Core & MIG Welding Machine with Multi-Voltage Plug for 120V or 240V - Inverter Technology Miller MIG Welders - MIG & Flux Core Welder Machine

FORNEY Easy Weld 140 Amp 120-Volt Flux-Cored Wire Feed Welder (No Gas Needed)

FORNEY Easy Weld 140 Amp 120-Volt Flux-Cored Wire Feed Welder (No Gas Needed)

Miller 907693 Multimatic 215 Multiprocess Welder - Versatile Multi-Process MIG, Flux-Cored & TIG Welder Machine - Portable Welding Machine with Wire Feeder, MIG Gun & Multi-Voltage Plug for 120V&240V

Miller 907693 Multimatic 215 Multiprocess Welder - Versatile Multi-Process MIG, Flux-Cored & TIG Welder Machine - Portable Welding Machine with Wire Feeder, MIG Gun & Multi-Voltage Plug for 120V&240V

7.7 score

LINCOLN ELECTRIC CO K2697-1 Easy MIG 140 Wire Feed Welder,

LINCOLN ELECTRIC CO K2697-1 Easy MIG 140 Wire Feed Welder,

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.