10 Best Wire Crimpers 2025 in the United States

Winner

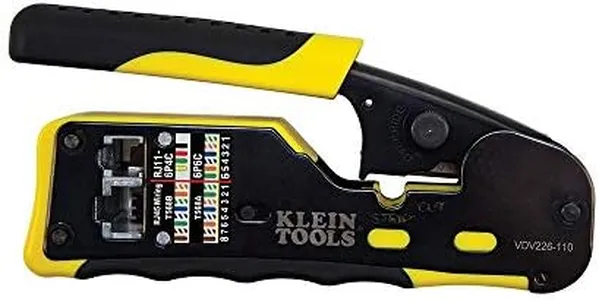

Klein Tools VDV226-110 Ratcheting Modular Data Cable Crimper / Wire Stripper / Wire Cutter for RJ11/RJ12 Standard, RJ45 Pass-Thru Connectors

The Klein Tools VDV226-110 Ratcheting Modular Data Cable Crimper is a versatile tool designed to streamline the installation of RJ11/RJ12 and RJ45 connectors for voice and data applications. Its crimping capacity is impressive, accommodating 4, 6, and 8 position modular connectors, which makes it suitable for a wide range of tasks. The type of crimp is precise, with flush trimming to the connector end face, reducing unintended contact between conductors and ensuring optimal performance.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Wire Crimpers 2025 in the United States

Winner

9.9 score

Klein Tools VDV226-110 Ratcheting Modular Data Cable Crimper / Wire Stripper / Wire Cutter for RJ11/RJ12 Standard, RJ45 Pass-Thru Connectors

Klein Tools VDV226-110 Ratcheting Modular Data Cable Crimper / Wire Stripper / Wire Cutter for RJ11/RJ12 Standard, RJ45 Pass-Thru Connectors

Chosen by 1227 this week

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.