10 Best Welding Hoods 2025 in the United States

Winner

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

The Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet boasts industry-leading optics with its 4C Lens Technology, providing excellent clarity and eliminating imperfections. This feature ensures that welders get the clearest view of their work, which is a significant advantage for precision tasks. The helmet has a perfect 1/1/1/1 optical clarity rating, meaning it excels in terms of blurriness, distortion, shade consistency, and angle uniformity. This makes it an excellent choice for those needing reliable and clear vision during welding tasks.

Most important from

1715 reviews

ESAB® Sentinel™ A60 Welding Helmet, Black Low-Profile Design, High Impact Resistance Nylon, Large Viewing Area 4.65 in x 2.80 in

The ESAB Sentinel A60 Welding Helmet stands out with its large viewing area (4.65 x 2.80 inches) and robust features, making it a great choice for welding tasks. The helmet's auto-darkening filter (ADF) offers a wide shade range (DIN 3/5–13) with fine adjustments in 0.5 increments, which is beneficial for different welding environments. The intuitive internal controls for sensitivity and delay, coupled with ESAB's True Color Lens Technology, ensure clear visibility and protection against harmful light.

Most important from

236 reviews

3M Speedglas Heavy-Duty Welding Helmet G5-01 with G5-01TW ADF and Adflo High-Altitude PAPR Assembly, Bluetooth, Natural Color Technology, 46-1101-30i

The 3M Speedglas Heavy-Duty Welding Helmet G5-01 is packed with features that cater to professional welders. One of its standout aspects is the G5-01TW Auto-Darkening Filter (ADF) with Variable Color Technology, allowing users to choose from three color options, enhancing visibility of the weld puddle, joint, and arc. The lens offers a wide range of dark shades (5, 8-13) and includes a tack welding comfort mode, making it versatile for various welding tasks. The auto-darkening feature is essential for protection and convenience during welding operations.

Most important from

41 reviews

Top 10 Best Welding Hoods 2025 in the United States

Winner

9.8 score

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

Chosen by 1270 this week

ESAB® Sentinel™ A60 Welding Helmet, Black Low-Profile Design, High Impact Resistance Nylon, Large Viewing Area 4.65 in x 2.80 in

ESAB® Sentinel™ A60 Welding Helmet, Black Low-Profile Design, High Impact Resistance Nylon, Large Viewing Area 4.65 in x 2.80 in

3M Speedglas Heavy-Duty Welding Helmet G5-01 with G5-01TW ADF and Adflo High-Altitude PAPR Assembly, Bluetooth, Natural Color Technology, 46-1101-30i

3M Speedglas Heavy-Duty Welding Helmet G5-01 with G5-01TW ADF and Adflo High-Altitude PAPR Assembly, Bluetooth, Natural Color Technology, 46-1101-30i

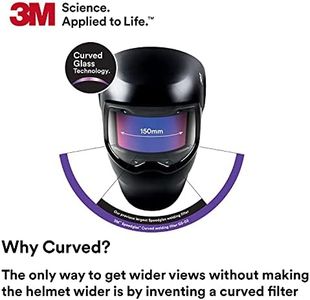

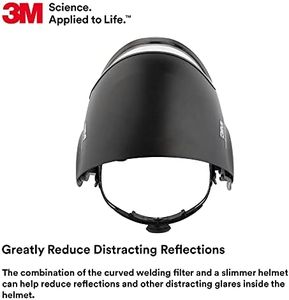

3M Speedglas Welding Helmet G5-02, Auto Darkening Welding Helmet Meets ISO 16321 TIG+ Standards, Light State 2.5, Curved Wide View ADF, Bluetooth Enabled, 4 Arc Sensors, Includes Welding Helmet Bag

3M Speedglas Welding Helmet G5-02, Auto Darkening Welding Helmet Meets ISO 16321 TIG+ Standards, Light State 2.5, Curved Wide View ADF, Bluetooth Enabled, 4 Arc Sensors, Includes Welding Helmet Bag

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.