10 Best Small Laser Engraver For Metal 2025 in the United States

Winner

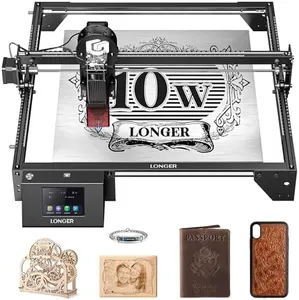

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

The LONGER Laser Engraver Ray5 10W is a robust option for those needing a small laser engraver for metal and other materials. It boasts a powerful 10W laser module and an advanced 240MHz ESP32 chipset, which allows for efficient and rapid processing. This makes it suitable for users who need to run multiple machines at once while maintaining high precision. The dual-beam technology ensures fine detail with a 0.06mm laser spot and a precision of 0.01mm, making it ideal for intricate designs on metal and other materials like wood, acrylic, and glass.

Most important from

303 reviews

LONGER Laser Engraver Ray5 5W Higher Accuracy DIY Laser Engraving Machine with 3.5" Touch Screen,Offline Usage Laser Cutter,400x400mm,0.08mm Laser Spot, CNC Laser Cutter for Wood Metal Acrylic Glass

The LONGER Laser Engraver Ray5 5W offers a range of impressive features for small metal engraving tasks. With a high-speed performance powered by a 240MHz ESP32 chipset, it can achieve speeds up to 10,000mm/min, making it suitable for quick and efficient engraving processes. The laser power of 5000MW facilitates precise engraving, supported by a laser spot size of 0.08mm and an engraving accuracy of 0.01mm.

Most important from

303 reviews

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, HD Laser Engraver for Jewelry, Metal, Wood, Leather

The xTool F1 2-in-1 Dual Laser Engraver is a versatile and portable engraving machine that stands out in its category due to several key strengths. With a laser power of 2W for infrared and 10W for diode lasers, it can handle a wide range of materials, including metal, wood, acrylic, and leather, making it a great choice for those needing to work with various surfaces.

Most important from

289 reviews

Top 10 Best Small Laser Engraver For Metal 2025 in the United States

Winner

10.0 score

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

Chosen by 1458 this week

LONGER Laser Engraver Ray5 5W Higher Accuracy DIY Laser Engraving Machine with 3.5" Touch Screen,Offline Usage Laser Cutter,400x400mm,0.08mm Laser Spot, CNC Laser Cutter for Wood Metal Acrylic Glass

LONGER Laser Engraver Ray5 5W Higher Accuracy DIY Laser Engraving Machine with 3.5" Touch Screen,Offline Usage Laser Cutter,400x400mm,0.08mm Laser Spot, CNC Laser Cutter for Wood Metal Acrylic Glass

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, HD Laser Engraver for Jewelry, Metal, Wood, Leather

xTool F1 2-in-1 Dual Laser Engraver, Lightning Speed Portable Laser Engraving Machine, HD Laser Engraver for Jewelry, Metal, Wood, Leather

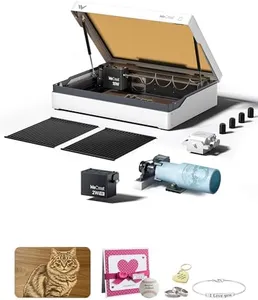

WECREAT Vista 10W Laser Engraving Machine with 9-in 1 Rotary, Smart HD Camera, Compact Diode Desktop Laser Engraver for Beginners DIY Hobbyist Wood Leather Glass Metal Jewelry Gifts Making

WECREAT Vista 10W Laser Engraving Machine with 9-in 1 Rotary, Smart HD Camera, Compact Diode Desktop Laser Engraver for Beginners DIY Hobbyist Wood Leather Glass Metal Jewelry Gifts Making

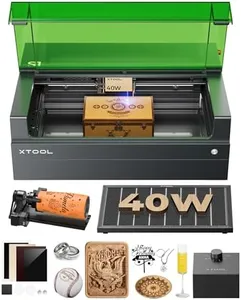

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

OMTech 50W Fiber Laser Engraver with LightBurn, Laser Engraving Machine with Red Dot Pointer, 7.9x7.9 Solid State Laser Marking Etching Machine for Metal Steel Gold Jewelry More

OMTech 50W Fiber Laser Engraver with LightBurn, Laser Engraving Machine with Red Dot Pointer, 7.9x7.9 Solid State Laser Marking Etching Machine for Metal Steel Gold Jewelry More

xTool F1 Lite Laser Engraver, 4000mm/s Lightning Speed Portable Laser Engraving Machine, Ultra HD Laser Engraver for Wood, Metal, Leather, Acrylic, Glass, and More.

xTool F1 Lite Laser Engraver, 4000mm/s Lightning Speed Portable Laser Engraving Machine, Ultra HD Laser Engraver for Wood, Metal, Leather, Acrylic, Glass, and More.

Longer Laser B1 48W Laser Engraver Cutter with Auto Air Assist, Working Speed Up to 600MM/S, DIY Laser Engraver for Wood and Metal, Paper, Acrylic, Glass, Leather, Working Area 17.72x17.32 inch

Longer Laser B1 48W Laser Engraver Cutter with Auto Air Assist, Working Speed Up to 600MM/S, DIY Laser Engraver for Wood and Metal, Paper, Acrylic, Glass, Leather, Working Area 17.72x17.32 inch

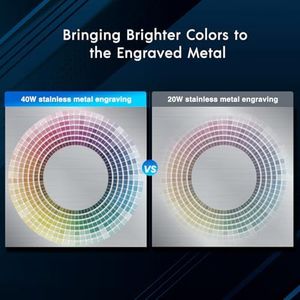

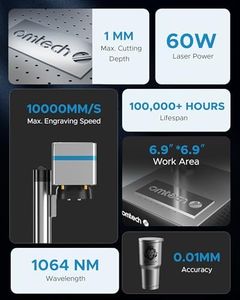

OMTech 60W MOPA Fiber Laser Engraver with Lightburn, 5.9"x5.9" Workbed Compact Laser Marking Machine for Metal Color Marking

OMTech 60W MOPA Fiber Laser Engraver with Lightburn, 5.9"x5.9" Workbed Compact Laser Marking Machine for Metal Color Marking

8.7 score

OMTech 30W Fiber Laser Engraver, LightBurn Compatible Laser Marking Machine with Red Dot Pointer for Metal Marking, 5.9"x5.9" Metal Etching Machine with 100,000 Hour Lifespan EZCad Included

OMTech 30W Fiber Laser Engraver, LightBurn Compatible Laser Marking Machine with Red Dot Pointer for Metal Marking, 5.9"x5.9" Metal Etching Machine with 100,000 Hour Lifespan EZCad Included

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.