10 Best Potters Banding Wheel 2025 in the United States

Winner

US Art Supply Large 12" Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

The US Art Supply Large 12" Diameter Sculpting Wheel is a solid choice for various artistic activities like pottery, sculpting, and cake decorating. Made from heavy-duty cast metal, it's designed to be nearly indestructible, offering durability and long-lasting performance. The wheel features a robust ball bearing mechanism that allows it to spin effortlessly, making your work smoother and more efficient.

Most important from

882 reviews

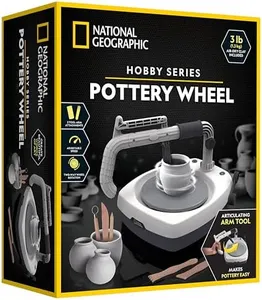

VEVOR Pottery Wheel 25cm Pottery Forming Machine with Sculpting Set Adjustable Feet Ceramic Pottery Wheel 280W Art Craft DIY Clay Tool for Ceramic Work Ceramics Clay

The VEVOR Pottery Wheel is a solid choice for both professional and amateur ceramic enthusiasts. Its 25cm diameter wheel offers ample space for pottery projects, and the compact structure ensures it doesn't take up too much room. The ABS basin makes cleaning easy and efficient, which is a definite plus for frequent use.

Most important from

684 reviews

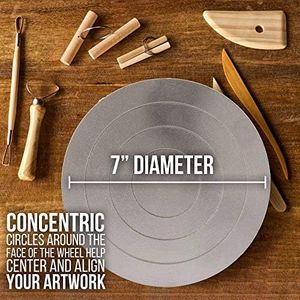

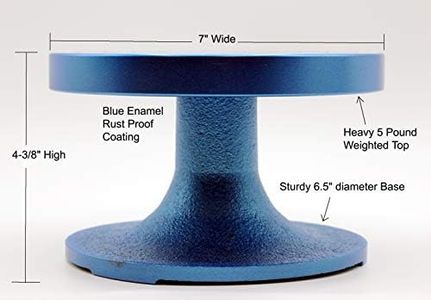

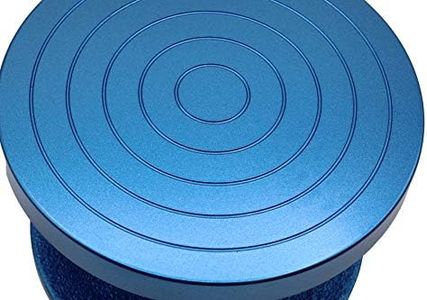

US Art Supply® 7” Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

The US Art Supply 7” Diameter Sculpting Wheel is a versatile tool designed for various artistic activities including ceramics, pottery, and cake decorating. Its all-metal construction ensures durability and longevity. The heavy-duty cast metal used for both the base and top makes it nearly indestructible, capable of handling up to 40 lbs of weight. This makes it a sturdy choice for heavy-duty tasks.

Most important from

639 reviews

Top 10 Best Potters Banding Wheel 2025 in the United States

Winner

10.0 score

US Art Supply Large 12" Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

US Art Supply Large 12" Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

Chosen by 1149 this week

VEVOR Pottery Wheel 25cm Pottery Forming Machine with Sculpting Set Adjustable Feet Ceramic Pottery Wheel 280W Art Craft DIY Clay Tool for Ceramic Work Ceramics Clay

VEVOR Pottery Wheel 25cm Pottery Forming Machine with Sculpting Set Adjustable Feet Ceramic Pottery Wheel 280W Art Craft DIY Clay Tool for Ceramic Work Ceramics Clay

US Art Supply® 7” Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

US Art Supply® 7” Diameter Sculpting Wheel- Heavy Duty All Metal Construction & Turntable with Ball Bearings

Shimpo- Banding Wheel 11 1/2" Diameter - Ball Bearing

Shimpo- Banding Wheel 11 1/2" Diameter - Ball Bearing

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.