10 Best Concrete Drills 2025 in the United States

Winner

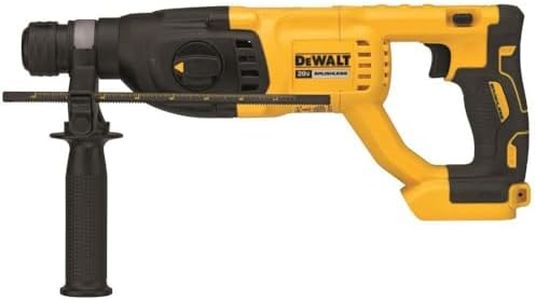

DEWALT 20V MAX SDS Rotary Hammer Drill, Cordless, 3 Application Modes, Bare Tool Only (DCH273B)

The DEWALT 20V MAX SDS Rotary Hammer Drill (DCH273B) is a powerful cordless tool designed for drilling in concrete with 2.1 Joules of impact energy. Its brushless motor and German-engineered mechanism ensure efficient performance and a good runtime. The drill offers three modes—Drill, Hammer Drill, and Chip—making it versatile for various tasks such as rod hanging, seismic attachments, and cable tray mounting. The SHOCKS ACTIVE VIBRATION CONTROL system enhances user comfort by reducing vibration, which is beneficial for prolonged use.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Milwaukee 2912-20 M18 Fuel 18V 1" Sds Plus Brushless Rotary Hammer

The Milwaukee 2912-20 M18 Fuel 18V 1" SDS Plus Brushless Rotary Hammer is a robust choice for those tackling concrete drilling tasks. It operates on an 18-volt battery, providing a substantial power output of 800 watts and a maximum rotational speed of 1330 RPM. This rotary hammer boasts a cordless design, enhancing mobility and convenience on job sites. The SDS Plus chuck system ensures quick and secure bit changes, while the AUTOSTOP control feature adds a safety layer by sensing and reacting to bind-ups.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!DEWALT 20V MAX Hammer Drill, 1/2", Cordless and Brushless, Compact With 2-Speed Setting, Bare Tool Only (DCD805B)

The DEWALT 20V MAX Hammer Drill (DCD805B) is a powerful, cordless, and brushless tool designed to handle tough concrete drilling tasks. It offers up to 40% more power than its predecessor when used with specific batteries, which is a significant advantage for demanding projects. The 2-speed settings, ranging from 0-650 to 0-2000 RPM, provide good control and precision, making it versatile for various tasks.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Concrete Drills 2025 in the United States

Sponsored

Winner

9.9 score

DEWALT 20V MAX SDS Rotary Hammer Drill, Cordless, 3 Application Modes, Bare Tool Only (DCH273B)

DEWALT 20V MAX SDS Rotary Hammer Drill, Cordless, 3 Application Modes, Bare Tool Only (DCH273B)

Chosen by 1322 this week

Sponsored

Milwaukee 2912-20 M18 Fuel 18V 1" Sds Plus Brushless Rotary Hammer

Milwaukee 2912-20 M18 Fuel 18V 1" Sds Plus Brushless Rotary Hammer

DEWALT 20V MAX Hammer Drill, 1/2", Cordless and Brushless, Compact With 2-Speed Setting, Bare Tool Only (DCD805B)

DEWALT 20V MAX Hammer Drill, 1/2", Cordless and Brushless, Compact With 2-Speed Setting, Bare Tool Only (DCD805B)

DEWALT FLEXVOLT ADVANTAGE 20V MAX* Hammer Drill, Cordless, 1/2-Inch, Tool Only (DCD999B)

DEWALT FLEXVOLT ADVANTAGE 20V MAX* Hammer Drill, Cordless, 1/2-Inch, Tool Only (DCD999B)

Milwaukee 2904-22 12V 1/2'' Hammer Drill/Driver Kit with (2) 5.0Ah Batteries, Charger & Tool Case Red

Milwaukee 2904-22 12V 1/2'' Hammer Drill/Driver Kit with (2) 5.0Ah Batteries, Charger & Tool Case Red

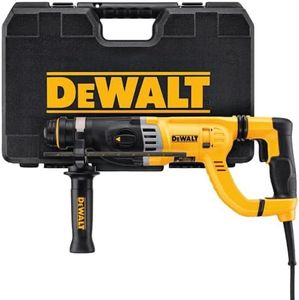

DEWALT DCH133B 20V Max XR Brushless 1” D-Handle Rotary Hammer Drill (Tool Only)

DEWALT DCH133B 20V Max XR Brushless 1” D-Handle Rotary Hammer Drill (Tool Only)

BOSCH HC8526 2-5/8 in. x 22 in. SDS-Max Rotary Hammer Core Bit Ideal for Applications in Concrete

BOSCH HC8526 2-5/8 in. x 22 in. SDS-Max Rotary Hammer Core Bit Ideal for Applications in Concrete

Cordless Rotary Hammer, SDS Plus

Cordless Rotary Hammer, SDS Plus

BOSCH 11255VSR Bulldog Xtreme 8 Amp 1 Inch Corded Variable Speed SDS-Plus Concrete/Masonry Rotary Hammer

BOSCH 11255VSR Bulldog Xtreme 8 Amp 1 Inch Corded Variable Speed SDS-Plus Concrete/Masonry Rotary Hammer

8.2 score

DEWALT Electric Drill, Spade Handle, 1/2-Inch, 9-Amp (DW130V)

DEWALT Electric Drill, Spade Handle, 1/2-Inch, 9-Amp (DW130V)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![[Upgraded] 12.3 Amp Rotary Hammer Drill, 1-1/4 Inch SDS-Plus 4 in 1 Multi-functional Heavy Duty hammer drill, Safety Clutch, Drill Chuck, for Concrete, Tile, Wall, Stones, Cement and Metal](https://images-proxy.bestreviews.guide/HV5OV5Fj2X1URDOB7yOTTVrASWg=/0x300/https://m.media-amazon.com/images/I/516tUZ7zj6L._AC_CX679_.jpg)