10 Best Big Heat Press 2025 in the United States

Winner

Delclynee 16" x 24" Slide Out Heat Press Machine for T Shirts, Clamshell Pull Out Lower Platen, Industrial-Quality Digital Sublimation Printer for Heat Transfer Vinyl

The Delclynee 16" x 24" Slide Out Heat Press Machine stands out with its large heat platen size, ideal for big designs and multiple items. The slide-out lower platen is a notable feature, enhancing safety by preventing accidental burns and offering better positioning for garments. The automatic locking mechanism provides added security during the process. Its non-stick coated heat platen ensures easy cleaning and less chance of scorching materials. The additional lower pad cover helps maintain cleanliness and prevent slippage, which is a thoughtful touch for consistent quality.

Most important from

1186 reviews

HTVRONT Auto Heat Press 2 - Heat Press Machine for T Shirts with Adjustable Pressure & Higher Heating Height, Heat Up Fast & Evenly Heat Press 15x15 for Sublimation, Puff HTV, Heat Transfer Project

The HTVRONT Auto Heat Press 2 is an efficient and versatile machine designed for various heat transfer projects. With a sizable 15x15 inch heating plate, it accommodates larger designs, ideal for t-shirts, hoodies, and even home decor items. The adjustable pressure feature allows for customization up to 170 lbs, making it suitable for different materials ranging from delicate fabrics to thicker items like hoodies and multi-layer transfers. This flexibility ensures professional-grade results for both small businesses and hobbyists.

Most important from

100 reviews

VEVOR 16x20 Heat Press, 1700W High Pressure Clamshell Heat Press Machine for T Shirts, Large Professional Digital Control Heat Transfer Machine for Sublimation, Vinyl, Heat Transfer Projects

The VEVOR 16x20 Heat Press is designed for those who require a versatile and efficient machine for various heat transfer projects, particularly T-shirts. Its large 16x20 inch heat platen is beneficial for larger designs, allowing for a range of applications including hats, mugs, and bags. One of the standout features is its adjustable high pressure, which accommodates different material thicknesses, ensuring a tight fit for optimal transfer results. Additionally, the machine heats up quickly to a maximum temperature of 570 °F (299 °C) due to its powerful 1700W heating element, which promotes even heat distribution across the platen. This can significantly enhance the quality of finished projects by providing consistent heat throughout the pressing process.

Most important from

1628 reviews

Top 10 Best Big Heat Press 2025 in the United States

Winner

9.9 score

Delclynee 16" x 24" Slide Out Heat Press Machine for T Shirts, Clamshell Pull Out Lower Platen, Industrial-Quality Digital Sublimation Printer for Heat Transfer Vinyl

Delclynee 16" x 24" Slide Out Heat Press Machine for T Shirts, Clamshell Pull Out Lower Platen, Industrial-Quality Digital Sublimation Printer for Heat Transfer Vinyl

Chosen by 1313 this week

HTVRONT Auto Heat Press 2 - Heat Press Machine for T Shirts with Adjustable Pressure & Higher Heating Height, Heat Up Fast & Evenly Heat Press 15x15 for Sublimation, Puff HTV, Heat Transfer Project

HTVRONT Auto Heat Press 2 - Heat Press Machine for T Shirts with Adjustable Pressure & Higher Heating Height, Heat Up Fast & Evenly Heat Press 15x15 for Sublimation, Puff HTV, Heat Transfer Project

VEVOR 16x20 Heat Press, 1700W High Pressure Clamshell Heat Press Machine for T Shirts, Large Professional Digital Control Heat Transfer Machine for Sublimation, Vinyl, Heat Transfer Projects

VEVOR 16x20 Heat Press, 1700W High Pressure Clamshell Heat Press Machine for T Shirts, Large Professional Digital Control Heat Transfer Machine for Sublimation, Vinyl, Heat Transfer Projects

Cricut EasyPress 3 Heat Press Machine (12 "x 10") with Heat Press Mat (15.5" x 12.5")

Cricut EasyPress 3 Heat Press Machine (12 "x 10") with Heat Press Mat (15.5" x 12.5")

HTVRONT Auto Heat Press Machine for T Shirts - Heat Press 15x15 with Auto Release - Heats Up Fast & Distribute Heat Evenly, Intelligent Heat Press Machines for HTV, Sublimation, Heat Transfer Projects

HTVRONT Auto Heat Press Machine for T Shirts - Heat Press 15x15 with Auto Release - Heats Up Fast & Distribute Heat Evenly, Intelligent Heat Press Machines for HTV, Sublimation, Heat Transfer Projects

Large Heat Press 32in x 40in: Clamshell Heat Press Machine for Textiles - Manual Operation, Digital Control, Sliding Design, 220V 1P, Ideal for Business Customers (32x40 220V,8000W (No Plug))

Large Heat Press 32in x 40in: Clamshell Heat Press Machine for Textiles - Manual Operation, Digital Control, Sliding Design, 220V 1P, Ideal for Business Customers (32x40 220V,8000W (No Plug))

RoyalPress 15" x 15" Color LED Industrial-Quality Digital Sublimation Heat Transfer Machine T-Shirt Heat Press Machine, 15" x 15", Black

RoyalPress 15" x 15" Color LED Industrial-Quality Digital Sublimation Heat Transfer Machine T-Shirt Heat Press Machine, 15" x 15", Black

16x24 Pneumatic Sliding Dual Platen Heat Press with Adjustable Infrared Positioning & Up-Sliding Function - Sublimation Transfer Machine for Professional Printing

16x24 Pneumatic Sliding Dual Platen Heat Press with Adjustable Infrared Positioning & Up-Sliding Function - Sublimation Transfer Machine for Professional Printing

VEVOR 8 in 1 Heat Press Machine 15x15 Inch, 360° Swing Away Shirt Press Machine - Digital Professional Heat Transfer Tshirt Press Machine, Sublimation Heat Press for T Shirts Hat Cap Mug Plate Blue

VEVOR 8 in 1 Heat Press Machine 15x15 Inch, 360° Swing Away Shirt Press Machine - Digital Professional Heat Transfer Tshirt Press Machine, Sublimation Heat Press for T Shirts Hat Cap Mug Plate Blue

8.7 score

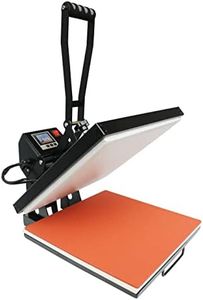

PowerPress Industrial-Quality Digital Sublimation Heat Press Machine for T Shirt, 15x15 Inch, Black

PowerPress Industrial-Quality Digital Sublimation Heat Press Machine for T Shirt, 15x15 Inch, Black

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.