10 Best 3 M Adhesive Tape 2025 in the United States

Winner

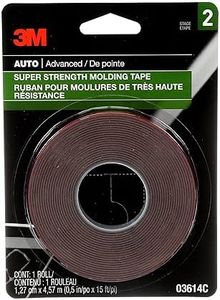

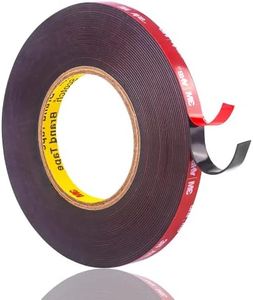

3M Super-Strength Molding Tape, 1/2 in x 15 ft, High Strength Double-Sided Adhesive, Permanently Attaches Side Moldings, Trim and Emblems to Interior and Exterior of Vehicles (03614)

The 3M Super-Strength Molding Tape is a versatile and durable double-sided adhesive tape designed for automotive use. Its high strength adhesive is ideal for permanently attaching side moldings, trims, and emblems both inside and outside vehicles. This tape boasts impressive weather resistance, allowing it to perform well in temperatures ranging from -40F to 250F, making it suitable for various climates.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

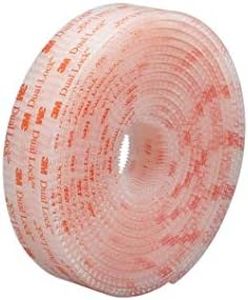

A summary of real customer reviews to highlight what shoppers are saying!3M SJ3560/CLR1333 Scotch SJ3560 Dual Lock 250 Reclosable Fastener: 1" x 10 ft., Clear

The 3M SJ3560 Dual Lock 250 Reclosable Fastener is a versatile adhesive tape designed for general-purpose use. It features an acrylic adhesive which bonds well to metals, glass, and medium-to-high surface energy plastics and paint, making it suitable for various applications. The polypropylene backing contributes to its durability and reliability.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best 3 M Adhesive Tape 2025 in the United States

Winner

9.7 score

3M Super-Strength Molding Tape, 1/2 in x 15 ft, High Strength Double-Sided Adhesive, Permanently Attaches Side Moldings, Trim and Emblems to Interior and Exterior of Vehicles (03614)

3M Super-Strength Molding Tape, 1/2 in x 15 ft, High Strength Double-Sided Adhesive, Permanently Attaches Side Moldings, Trim and Emblems to Interior and Exterior of Vehicles (03614)

Chosen by 1479 this week

3M SJ3560/CLR1333 Scotch SJ3560 Dual Lock 250 Reclosable Fastener: 1" x 10 ft., Clear

3M SJ3560/CLR1333 Scotch SJ3560 Dual Lock 250 Reclosable Fastener: 1" x 10 ft., Clear

3M Aluminum Foil Tape 3340, 2.5" x 50 yd, 4.0 mil, Silver, HVAC, Sealing and Patching Hot and Cold Air Ducts, Fiberglass Duct Board, Insulation, Metal Repair

3M Aluminum Foil Tape 3340, 2.5" x 50 yd, 4.0 mil, Silver, HVAC, Sealing and Patching Hot and Cold Air Ducts, Fiberglass Duct Board, Insulation, Metal Repair

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.